Products > Fixtured Screwdrivers

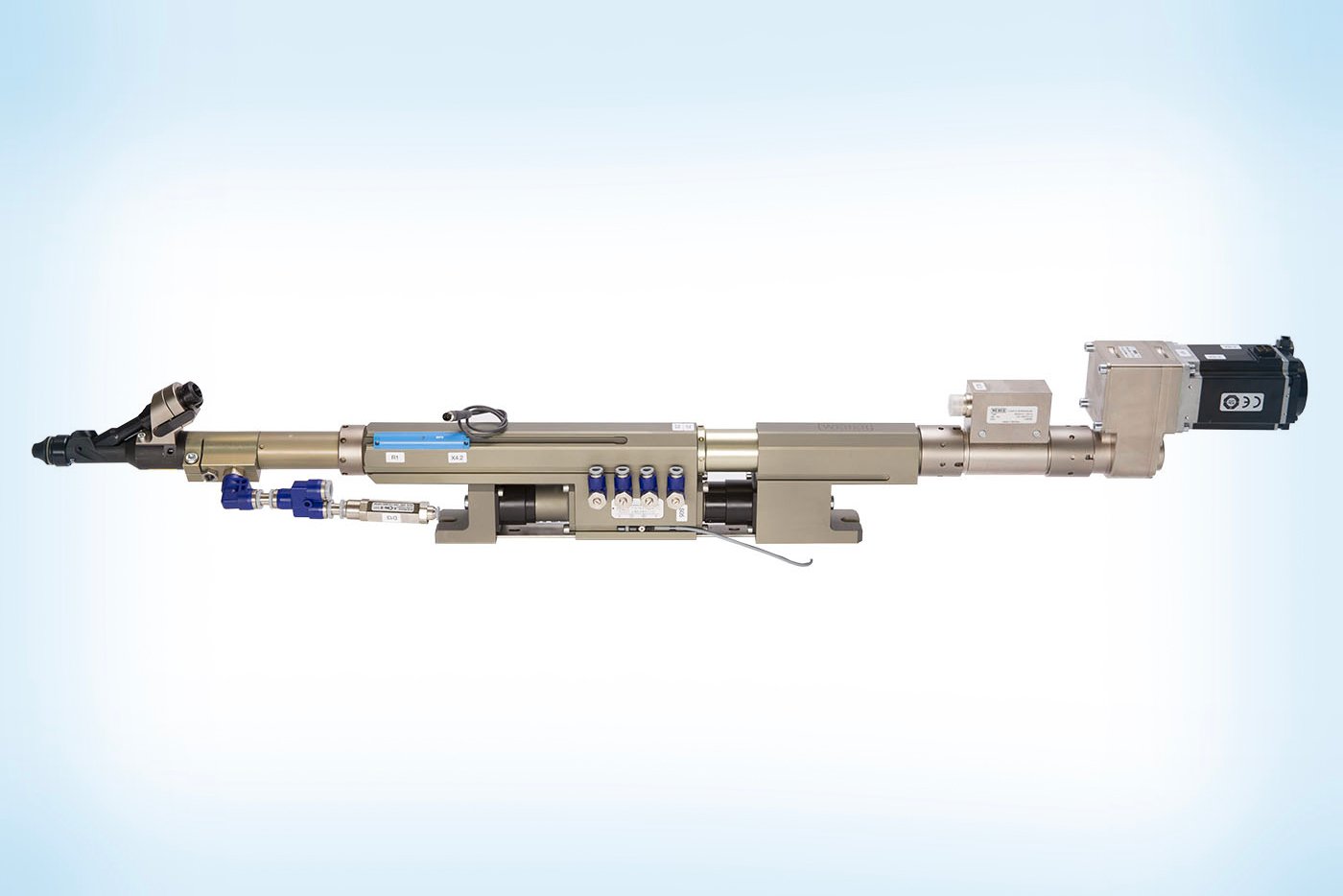

Vacuum Fixtured Screwdriver SEV

Screwdriving technology for hard to reach screwdriving locations

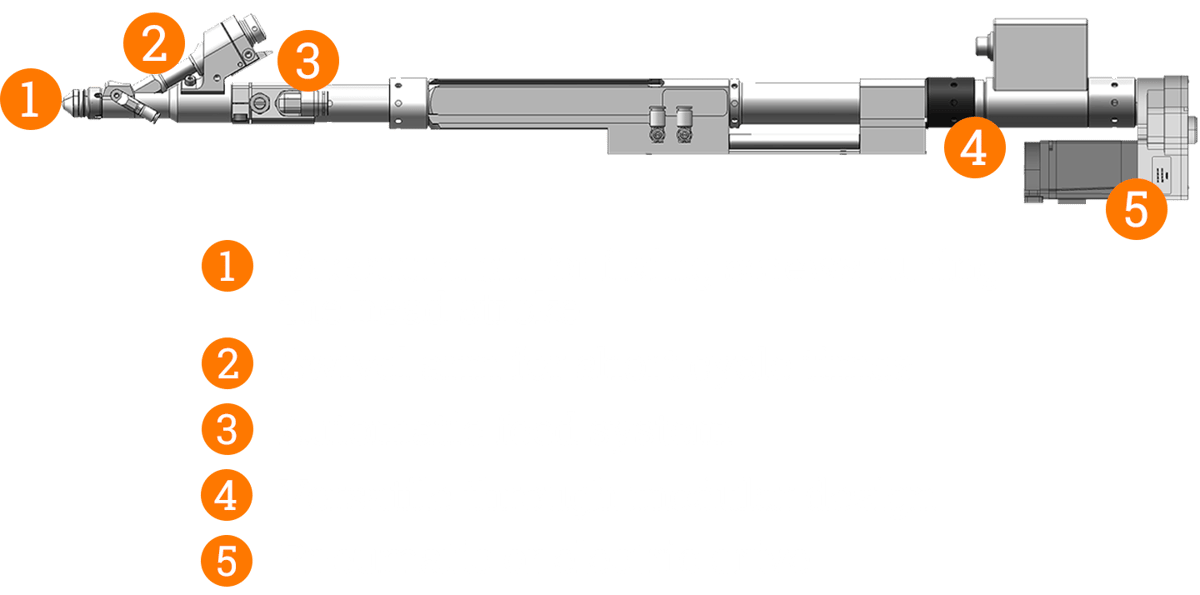

The WEBER SEV Fixtured systems feature a highly reliable and rugged design which is the standard within the industry for fixed spindles. These units are for use on a single stage application or when a robot or other slide will bring the driver spindle closer to the work pieces for installation of the fastener. The special Vacuum nosepiece and Vacuum bit can be instructed to self advance its bit stroke device and install fastener while detecting that the depth was achieved or not. When the start signal is given usually through a PLC control system to a solenoid valve the vacuum bit advances forward out of the jaws to expose the bit and fastener . This proven design can get into access location normally unachievable by conventional means, and allows fasteners to be installed down into deep recesses. Only the legendary WEBER reputation of reliability could provide this level of technical solution. Customization is performed on most systems to ensure the utmost functionality for each fastener size and style. This device can accommodate almost any style of Pneumatic or Electric motor drives and can be used singly or in multiples for more complex fastening . They can be used at any angle and even upside down for those difficult inverted applications., and these are often fitted with sensors to provide input to a PLC for control or reporting functions.

Customer-provided drives

The open system of the fixtured automatic screwdriving system SEV allows you to integrate customer-provided drives. This makes it easy to integrate the SEV in existing assembly lines with existing drives and controllers. Subsequent conversion to WEBER components is possible at any time.

Features

• Screwdriving spindle with vacuum technology to ensure reliable fastener insertion in hard-to-reach locations with extremely limited access

• Automatic feed system

• Pneumatic or electric drive

• ‘Feed While You Drive’ technology

• Depth verification analog or digital

• Optional active depth