2 min read

Reduce Cycle Time with our "Feed While You Drive" Technology

By: Carey Dupuy Feb 20, 2025 8:00:00 AM

Mike Rabasco, CEO of WEBER USA, explains our "Feed While You Drive" technology. He also dives into some of the benefits of this industry-leading technology, such as reduced cycle time. Reducing cycle times in screwdriving assembly offers numerous benefits, including increased production efficiency, lower operational costs, and improved overall throughput.

By minimizing the time spent on each fastening process, manufacturers can assemble more products in less time, leading to higher output without compromising quality. Shorter cycle times also reduce equipment wear and energy consumption, extending the lifespan of machinery and lowering maintenance costs. Additionally, a more efficient process minimizes downtime and bottlenecks, allowing for smoother workflow and greater flexibility in meeting production demands. Ultimately, faster cycle times enhance profitability by maximizing productivity and optimizing resource utilization.

Learn more about this technology straight from Mike in this video or read the transcription below

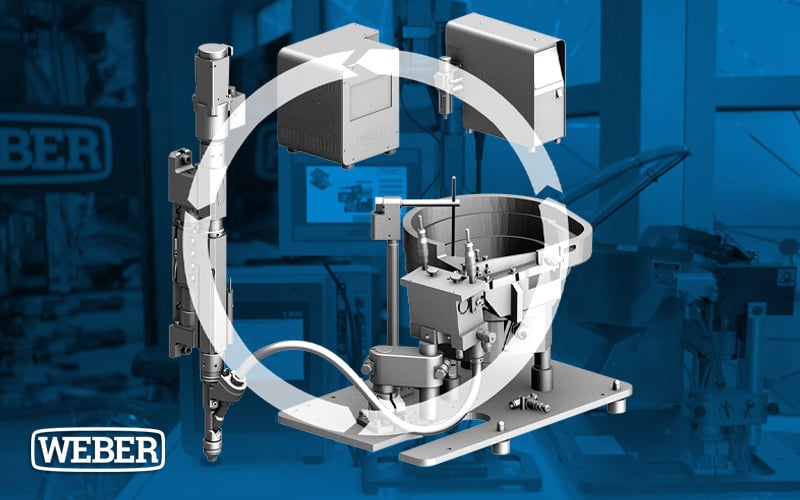

The basis for this industry-leading technology is the unique feed head design of our screwdriving systems. WEBER was the first, and remains one of the few manufacturers in the industry, to incorporate a swivel screw feed arm directly into the feed head. The swivel arm holds the next fastener in place, ready to be driven. This method eliminates the time spent waiting for the next fastener to travel all the way from the feed system, through the feed tube, into the head, naturally reducing the cycle time by an average of 2 to 3 seconds.

WEBER’s “Feed while you drive” technology has proven to significantly increase production capability which means a direct impact to your bottom line.

We understand—screwdriving automation can be complex, and keeping your production line running smoothly is no easy task. That’s where WEBER comes in. As pioneers in automated screwdriving technology since 1956, we have over half a century of innovation behind us.

Our team of world-class engineers and technicians has developed solutions for virtually every application, and we’re ready to bring that expertise to your operation.

Our systems are built for long-term reliability. Once they’re integrated into your line, you can focus on what matters most—without worrying about downtime or disruptions.

Automation is challenging, but with WEBER, it doesn’t have to be.